QUALITY INDICATORS OF DRINKING WATER

July 18, 2023

FOOD DEFENSE THROUGH HISTORY OF INCIDENTS

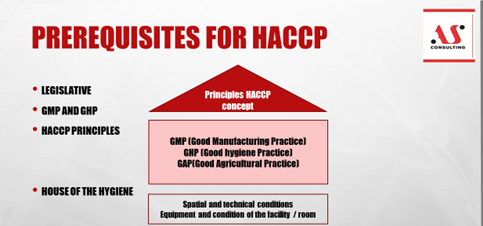

August 14, 2023Can we imagine the production of safe food in production facilities that do not have pest control measures in place? Or are the rules of good hygiene practice not being applied? No measures in place to prevent cross-contamination? What would a HACCP study look like then and would it make sense?

The importance of prerequisite programs (PRP’s) can be seen here: prerequisite programs in the food safety management system are measures that ensure the basic conditions for working in a safe environment for the production of health-safe food. These are the measures of good hygiene (GHP) and good manufacturing practice (GMP), which are the basic conditions and activities for creating such an environment in which safe food can be produced.

PRP as the basis of a food safety management system

The HACCP system is today the basis of the food safety management system of all GFSI recognized standards. In order to establish and maintain the HACCP system and then other standards of the food safety management system, the following prerequisites are necessary:

GMP (good manufacturing practice) – a set of procedures that manage the conditions of the working environment and provide the basis for the production of safe food products.

GHP (good hygiene practice) – a set of procedures that manage the hygiene of the work environment and provide the basis for the production of safe food products.

GAP (good agricultural practice) – a set of procedures that manage the conditions of primary production and provide the basis for the production of safe food products.

Prerequisite programs that can be implemented in food companies will be shown through two technical specifications that define the requirements for the prerequisite programs:

1.ISO22002-1:2009

2. BS PAS 222:2011

Technical specification ISO22002-1: 2009

Technical specification ISO22002-1:2009 was developed by the International Organization for Standardization (ISO – International Organization for Standardisation) and represents requirements for prerequisite programs (to be established by companies that are part of the food chain) and represents support for the ISO22000 standard with the aim of being used in combination with it.

This Technical Specification specifies detailed requirements to be specifically considered in relation to ISO 22000:2005, 7.2.3:

a) construction and layout of buildings and associated utilities;

b) layout of premises, including workspace and employee facilities;

c) supplies of air, water, energy and other utilities;

d) supporting services, including waste and sewage disposal;

e) suitability of equipment and its accessibility for cleaning, maintenance and preventive maintenance;

f) management of purchased materials;

g) measures for the prevention of cross-contamination;

h) cleaning and sanitizing;

i) pest control;

j) personnel hygiene.

In addition, this Technical Specification adds other aspects which are considered relevant to manufacturing

operations:

1) rework;

2) product recall procedures;

3) warehousing;

4) product information and consumer awareness;

5) food defence, biovigilance and bioterrorism.

Technical specification BS PAS 222:2011

This specification has been prepared by the British Standards Institution (BSI) to specify requirements for Prerequisite Programs (PRPs) to help control food and feed safety hazards and is intended to assist organizations in those industries by setting out requirements that are specific for the production and supply of animal feed, animal feed and ingredients. The specification considers the following requirements:

a) site and associated utilities;

b) processes, including workspaces and employee

facilities;

c) supplies of air, water and other utilities;

d) supporting services, including waste disposal;

e) suitability of equipment and its accessibility for

cleaning, maintenance and preventive maintenance;

f) management of ingredients;

g) management of medications;

h) measures for the prevention of contamination;

i) sanitation;

j) pest control;

k) personnel hygiene;

In addition, this PAS adds other aspects that are considered relevant to animal food and feed manufacturing operations:

l) rework;

m) product withdrawal procedures;

n) warehousing and transportation;

o) formulation of products;

p) specifications for services;

q) training and supervision of personnel;

r) product information;

s) food defence, biovigilance and bioterrorism.