NONCONFORMITIES AND CORRECTIVE ACTIONS

September 5, 2024

SUPPLIERS AUDITS

October 3, 2024To obtain a product that is of appropriate quality and, most importantly, health-safe, in addition to adequate raw materials and packaging, many other significant factors must be considered, which we will address in this blog.

One of the most important areas in food production is the management of the equipment used in operations and processes. Besides the fact that breakdowns and downtimes can cause significant financial losses, inadequate equipment can also jeopardize the safety of the products. Therefore, we will go through the requirements of food standards related to equipment management and maintenance, and clarify details that may cause confusion.

Why do food standards address process equipment at all?

- Process equipment is in direct contact with raw materials and/or the product, posing potential safety hazards, such as: parts of the equipment that may end up in the product, the transfer of constituents (heavy metals) from the equipment to the product, the penetration of oils, lubricants, and other potential hazards into the product.

Where to start?

- With a hazard analysis. What potential hazards may arise from the equipment: metal parts, materials that must not come into contact with food, damages, oil and fluid leaks, wires, connections, etc. At which stage of the process do we have potential hazards from the equipment? What preventive measures does the company implement?

What are the requirements of food standards regarding equipment?

- Equipment must be adequately designed and intended for the intended use. Before being put into operation, new equipment must be validated to demonstrate compliance with food safety, product quality, legality, authenticity, and customer requirements.

- There must be compliance requirements for all equipment and utensils that may affect products (in the form of declarations of conformity, technical specifications, etc.).

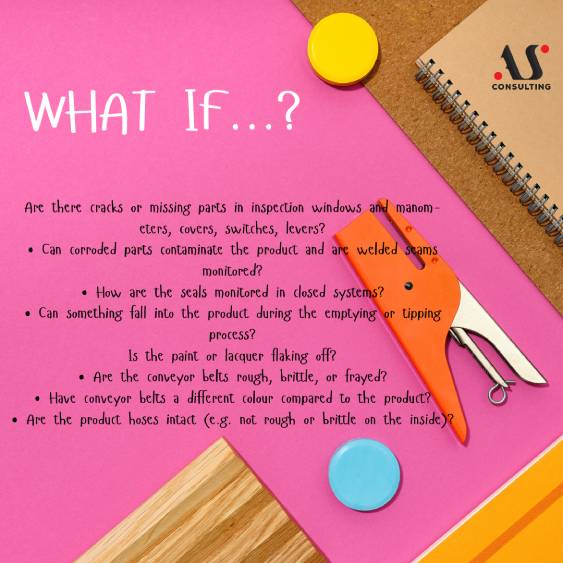

- All equipment must be in such a condition that it does not compromise the safety and quality of the product (are there any cracks or missing parts; is the paint or coating flaking; are there parts that could fall into the product; how are seals and joints monitored; what is the condition of conveyor belts in contact with open products; what is the state of pipes and hoses: rough surfaces, damages, etc.).

What are the requirements of food standards regarding equipment maintenance?

- Preventive maintenance plan: the company must have a documented, implemented, and maintained preventive maintenance plan that covers all critical equipment (including transport and storage facilities) to ensure food safety, product quality, and legality. Why preventive maintenance? To prevent potential hazards to safety, quality, and authenticity of food, as well as breakdowns and downtimes in production.

- During repairs and maintenance, and afterwards, attention must focus on ensuring product safety; records of all types of interventions must be kept (how you ensured that all parts were returned to their place after repairs; whether any parts are missing or excessive; whether the equipment was checked before approval; whether work surfaces were cleaned after maintenance activities, etc.).

- What do you think about duct tape? 😊 Temporary repairs will be made to avoid compromising food safety and product quality. Such work should be documented and a short-term deadline should be set for resolving the issue. Thus, duct tape is certainly not a solution and poses an additional risk to product safety.

- U slučaju da angažujete spoljnog pružaoca usluge, sve zahteve standarda morate definisati kroz ugovor.

U slučaju da imate nejasnoća u vezi zahteva koji se odnose na održavanje i opremu, obratite se za pomoć našoj Agenciji!!!