CLAIMS ON FOOD PRODUCTS

January 6, 2025

FOOD DEFENCE – THREE ELEMENT METHODOLOGY

January 26, 2025I believe that everyone involved in food safety is already familiar with the term “food defence.” Food defence is the protection of food from intentional contamination by chemical, physical, biological, or radiological agents with the intent to cause harm. Food defence is an important element for protecting food from potential external and internal threats. How can companies protect themselves from intentional contamination? Companies are required to conduct a hazard analysis and review all potential threats to food safety, then implement preventive measures to truly protect their food products. More about this in our article:

In this article, we will focus on the KAT methodology: Key Activity Types (KATs).

Basic Concepts (Requirements) that Companies Must Meet Regarding the Implementation of Food Defence Strategies

According to: Mitigation Strategies to Protect Food Against Intentional Adulteration: Guidance for Industry (Office of Analytics and Outreach, Food Defence and Emergency Coordination Staff, in the Center for Food Safety and Applied Nutrition at the U.S. Food and Drug Administration), to develop an adequate food defence plan, the following concepts must be understood:

• Intentional adulteration (IA) – intentional falsification, which includes:

- Acts intended to cause harm to public health (such as terrorism targeting the supply chain);

- Acts by dissatisfied employees, consumers, or competitors (intended to harm the company’s reputation);

- Economically motivated fraud (intended to gain economic benefit).

For a company to protect itself from all potential (intentional) threats to product safety, it is necessary to prepare a written food defence plan, which includes:

- Vulnerability assessment to identify significant vulnerabilities and process steps that can be taken;

- Mitigation strategies for each process step and written explanations about them;

- Food defence monitoring procedures to implement mitigation strategies;

- Corrective action procedures for food defence that must be taken if mitigation strategies are not properly implemented;

- Food defence verification procedures for verification activities, in line with the nature of the mitigation strategy and its role in the facility’s food defence system.

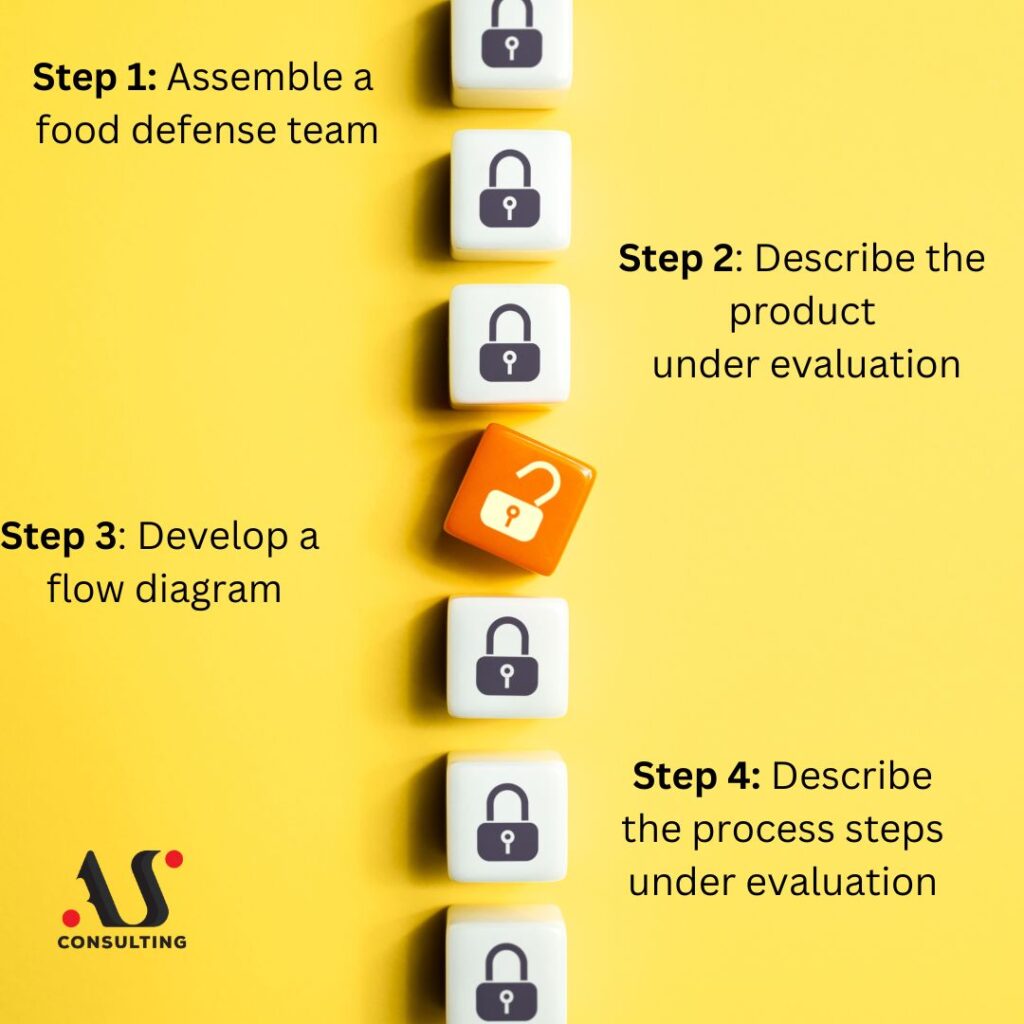

Vulnerability Assessment

Vulnerability assessment is a core component of your overall food defence plan. Vulnerability assessments can be conducted using a selected methodology. Preliminary steps to conduct a vulnerability assessment include:

- Assembling a food defence team

- Describing the product being assessed

- Developing a process flow diagram

- Describing the process steps

There are no mandatory requirements for which methodology you should choose, but each hazard assessment must consider the following:

- The potential impact on public health (e.g., severity and scope) if a contaminant is added;

- The degree of physical access to the product;

- The ability of an attacker to successfully contaminate the product.

KAT Methodology

The KAT methodology – Key Activity Types (KAT) – was developed by the FDA, where, through more than 50 vulnerability assessments, the most vulnerable activities were identified, regardless of the type of food.

The four KATs are:

- Receiving and unloading bulk liquids;

- Storing and handling liquids;

- Handling secondary ingredients;

- Mixing and similar activities.

Receiving and unloading bulk liquids is one of the four key activities because if a contaminant is added to the liquid, there is a significant possibility that it will mix into the liquid due to significant splashing, movement, or turbulence associated with the receiving or unloading activity. This does not apply to liquids transported in sealed containers or packaging, as the liquid does not use the vehicle as a container for bulk cargo.

Storing and handling liquids includes:

- Storing or holding liquids (bulk or non-bulk) either in storage tanks or other containers at the facility, or

- Handling, measuring, overpressure, or other types of intermediate process tanks used to control the flow of liquid ingredients or products through the production system.

These activities fall into the four key activities because if a contaminant is introduced, there is a high likelihood of it mixing with the liquid due to the existing mixing process applied when, for example, liquid enters or exits a tank or when dosing liquid ingredients.

Handling secondary ingredients includes any point, step, or procedure where people manipulate dry or liquid secondary ingredients (e.g., inclusions, minor ingredients, processing aids, and food additives) before or during their addition to the product flow. These are key activities because a contaminant could be intentionally introduced into a relatively small quantity of an ingredient and thus make its way into the final product.

Mixing and similar activities include points, steps, or procedures where the primary purpose or result is:

- Mixing;

- Homogenization;

- Grinding;

- Coating.

These are key activities because a potential contaminant successfully added at one of these steps would generally be easily dispersed throughout the product due to the nature of the activity.

The methodology involves identifying the four key activities (with a written explanation of why they were identified), followed by conducting a vulnerability assessment and implementing mitigation strategies.

Process steps that do not fit into the four key activities do not require mitigation strategies.

If you would like to learn more about KAT (and other food defence methodologies), feel free to contact our Agency for assistance!!!