FOOD PACKAGING

December 20, 2022

WITHDRAWAL AND RECALL OF FOOD PRODUCTS

January 17, 2023In the quality and food safety standards, we encounter requirements related to compressed air, which emphasize the need for the quality of compressed air that comes into contact with food or primary packaging to be monitored with a frequency that depends on the hazard analysis. Bearing in mind that the legislation does not set clearer criteria, the problem of how to successfully meet the requirements related to compressed air is often encountered. Let’s try to clarify this topic.

What exactly is compressed air? Nothing but compressed ambient air (air under pressure greater than atmospheric) that comes into contact with food or primary packaging via air compressors. Compressed air is used in almost all branches of the food industry, e.g. for evaporating liquids or as a transport medium for dry food, then in canning, freezing and dehydration processes; compressed air is used for blowing, cleaning, sorting, cutting, shaping and transporting food products.

As we explained, the compressed air originates from the ambient air of the environment where the compressor is located, so the quality of the compressed air depends on the quality of the ambient air: impurities increase depending on the degree of compression. Impurities that can be found in compressed air are:

- Solid impurities: this includes, for example, dirt particles such as pollen, dust fibers, soot and heavy metals. Contamination with such solids damages the shelf life and taste of food.

- Oils and oil vapor: mineral oils are used for cooling and sealing in many types of compressors, which is why the resulting compressed air is contaminated with oil.

- Water or moisture: when wet atmospheric air is compressed in the compressor, compressed air saturated with moisture is obtained: additional moisture can occur and/or increase by condensation, during the movement of compressed air through the pipeline network. Moisture causes damage to cut hygroscopic products such as powdered products, salt, sugar, spices.

- Microorganisms and germs: they find ideal conditions after compressing the ambient air with a compressor. They can easily reproduce in heated and moisture-saturated compressed air.

In this way, contaminants from untreated air can come into contact with food or primary packaging and directly harm the health of users.

METHODS OF CONTACT WITH COMPRESSED AIR. Contact with compressed air can be:

- Direct: compressed air is directed directly to the product or primary packaging or production equipment and preparation surfaces e.g. spraying; air knives (cutting / peeling / cooling); spraying / coating; transfer (movement); direct cooling; packaging; drying.

- Indirect: this type of contact occurs when compressed air reaches a certain distance to the product and is diluted with ambient air, e.g. blowing of packaging surfaces for quality control and transportation of food packaging.

COMPRESSED AIR CONTROL AND FOOD SAFETY

In order to ensure the quality of compressed air and prevent a negative impact on the quality and safety of food, the first step is to establish prerequisite programs, such as good hygiene practices, equipment maintenance, training.

The next step is to include compressed air in the HACCP risk analysis, ensuring that relevant personnel understand the potential hazards with compressed untreated or partially treated compressed air. Also, when potential hazards are recognized, preventive measures will be implemented.

The safe use of compressed air in the food industry requires filtration, appropriate measures to ensure oil-free operation and efficient drying of the compressed air. The necessary components such as filters, dryers, adsorbers with activated carbon or catalysis units must be coordinated with each other and must function reliably even at different loads.

It is necessary to constantly monitor the quality of compressed air with appropriate measuring technology. Only in this way can the quality of compressed air be continuously measured and documented.

What are the quality criteria of compressed air?

Here we come to a problem, because unlike, for example, water, where there is a clear legal regulation, with compressed water we have national and international guidelines, but they are not legally binding. We also have no help from standards related to food safety as we can see in the example of the BRC Food standard ver 9: requirement 4.5.3. ” Air and other gases used as an ingredient or that are in direct contact with products shall be monitored to ensure this does not represent a contamination risk. Compressed air that is in direct contact with the product shall be filtered at point of use.”

And what is a problem for all of us is exactly what are the criteria and limits, following which would prove the safety of compressed air.

STANDARD ISO 8573-1

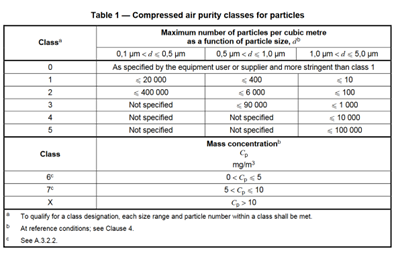

The International Organization for Standardization has issued the ISO 8573-1 standard, which refers to compressed air: it determines the permissible amount of pollutants per cubic meter of compressed air. In the different quality classes, the main pollutants solid particles, water and oil are defined by the three corresponding indicators of particle size, residual moisture and oil content.

Unfortunately, what we are most interested in, which are microbiological criteria, are not defined by this standard. How then to determine microbiological criteria and permissible limits? As food standards require: based on hazard analysis! The company is the one that knows best its potential hazards that can appear in: air, equipment, contact surfaces. Also, compressed air system piping can harbor mold, yeast, or bacteria. We will set the limits again through hazard analysis: what is the permissible limit of microbiological hazards above which the safety of our products is endangered?

Testing methods:

There are two primary methods for microbial air sampling: active and passive monitoring.

In active monitoring, compressed air is injected into or onto a collection medium (eg, a Petri dish with a nutrient agar-based test medium) over a period of time. The collected culture can then be analyzed (ie bacteria and/or fungi, colony forming units (CFU) counted and identified if necessary).

In passive monitoring, sedimentation plates (Petri dishes) are opened and exposed to air for specific periods of time to determine which microbiological particles may be present in the environment as they may be deposited from the ambient air and onto the surface of the media. Petri dish. These plates are then incubated and analyzed.

The frequency of testing is at least 2 times a year or more often, depending on the risk analysis.